1.The principle of pressure swing adsorption

Using the principle of the difference in the diffusivity of oxygen and nitrogen in the carbon molecular sieve in the air, oxygen molecules are adsorbed by carbon molecular sieves in large quantities, and nitrogen molecules are enriched in the gas phase to achieve a physical principle of separation of oxygen and nitrogen.

Oxygen adsorption capacity of carbon molecular sieves will be significantly different with the pressure change, reduce the pressure, you can desorption of carbon molecular sieve adsorbed oxygen molecules. The carbon molecular sieves are regenerated so that carbon molecular sieves can be recycled and used repeatedly.

In the case of adsorption equilibrium, when any adsorbent adsorbs the same gas, the higher the gas pressure, the greater the amount of adsorbent adsorbed. Conversely, the lower the pressure, the smaller the amount of adsorption. as the picture shows:

As the air pressure rises, carbon molecular sieves will adsorb large amounts of oxygen, carbon dioxide, and moisture. When the pressure drops to atmospheric pressure, the adsorption of oxygen, carbon dioxide, and moisture by carbon molecular sieves is very small.

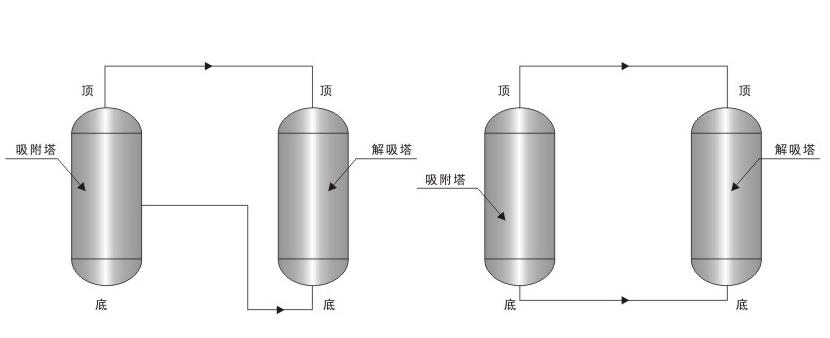

The pressure swing adsorption equipment mainly consists of A and B adsorption towers and control systems equipped with carbon molecular sieves. When compressed air (typically 0.85 MPa) passes through the A column from the bottom up, oxygen, carbon dioxide, and moisture are adsorbed by the carbon molecular sieve, while nitrogen is passed through and flows out of the top of the tower. When the molecular sieve adsorption in the tower A is saturated, it is switched to the tower B for the above-mentioned adsorption process and at the same time the tower A molecular sieve is regenerated. The so-called regeneration, that is, the adsorption tower gas discharged to the atmosphere so that the pressure rapidly reduced to atmospheric pressure, the molecular sieve adsorption of oxygen, carbon dioxide and moisture from the molecular sieve to release the process.

2. Nitrogen system process

The compressed air is purified to remove a large amount of oil and water, and then enters an air buffer tank. Further, the filter and the activated carbon filter further remove the harmful substances such as moisture and micro-oil mist, and then enter the two filled adsorbents after being buffered by the air buffer tank. Nitrogen adsorption unit for pressure swing adsorption system.

The clean compressed air enters from the bottom of the adsorption tower. After the air is diffused by the air diffuser (universal spiral or porcelain ball), it enters the adsorption tower evenly and undergoes oxygen and nitrogen adsorption and separation. Then nitrogen flows from the outlet end into the nitrogen buffer tank. This nitrogen-producing process takes about 1 minute, after which pressure is equalized and decompressed (to atmospheric pressure) to remove the adsorbed impurity components (mainly oxygen) to complete regeneration of the adsorbent. The two adsorption towers are alternately cycled to continuously feed raw air to continuously produce a purity of ≥99.999% nitrogen, a production capacity of 30 Nm3/h, a nitrogen output pressure of 0.6 MPa, and a nitrogen atmospheric dew point of -40°C.

3. Nitrogen configuration instructions

A.Adsorption tower structure features

The adsorption tower is the core part of the entire nitrogen production system. The oxygen-nitrogen separation process in the air is completed in the adsorption tower.

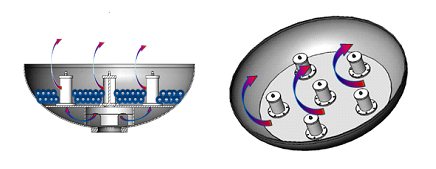

As shown in the above figure, the adsorption tower is composed of various parts in the illustration. Its advanced internal structure design (universal spiral or filled ceramic ball changes the airflow direction) makes the airflow even and smooth into the molecular sieve bed, minimizing the gas The collision of molecules with carbon molecular sieves is more conducive to ensuring the purity of nitrogen and ensuring the long-term effective use of carbon molecular sieves. The high-speed impact of gas on the molecular sieve in the adsorption process is fully considered and avoided, the phenomenon of molecular sieve pulverization brought about by the high-velocity impact of the gas flow is avoided, and the phenomena that the powdered powder enters into the pipelines and valves and causes the valves to leak and jam are avoided.

The original molecular sieve composite bed structure ensures that the water content of the air entering the carbon molecular sieve is lower than the level of -40°C, so that the carbon molecular sieve will not absorb excessive water and affect the decrease of the mechanical strength, which is beneficial to the long-term service life of the carbon molecular sieve.

The adsorption tower adopts advanced cylinder compression technology, and it enters the working state when the nitrogen generator starts working. Under the working state, the piston always guarantees that the molecular sieve will be compacted, and will not break the carbon molecular sieve at the same time, avoiding the high-speed impact of air flow. Molecular sieve powdering phenomenon. The delay settling alarm system is set in the pressing device. When the stroke of the compression cylinder exceeds the set stroke, the automatic limit alarm system will alarm the photoelectricity. The pressing device is pressed by the spring, pressed by the coir pad, and the air bag. Comparing with the pressing device, the reliability is stronger and more convenient. When the cylinder is lowered to the middle position, the control system will give an alarm. At this time, molecular sieves need to be added and sound and light alarms can be realized on the control panel.

Special inequality pressure equalization process

The equipment uses an unequal pressure equalization process. The unequal pressure equalization process improves the lower pressure equalization position of the traditional equalization pressure process. When the inequality equalizes, the gas is drawn from the middle of the adsorption tower that has been adsorbed to the bottom of the desorption adsorption tower. According to the nitrogen purity of the nitrogen generator, it is gradually increased from the bottom to the top in the adsorption tower, so that the nitrogen gas with higher purity is from The adsorption tower is evenly pressed to the desorption tower to increase the nitrogen concentration of the absorption tower, and at the same time reduce the understanding of the adsorption of oxygen by the carbon molecular sieve in the absorption tower and improve the utilization rate of the carbon molecular sieve. The unequal pressure equalization process is more reasonable, scientific, and mature than the equal pressure equalization process. The direct effect is that the nitrogen recovery rate is increased and the gas production volume is increased. The indirect effect is to save energy consumption. At the same time, nitrogen recovery and utilization of carbon molecular sieves have also been improved.

B.Molecular sieve filling

The patented microwave oscillating packing technology makes the molecular sieve packing more uniform and dense, ensuring that the molecular sieve does not produce a fluidized state during the adsorption process, and does not need to regularly replenish the expensive carbon molecular sieve.

C.Pressing device

1、composition

Compression device cylinder consists of cylinder block, piston, piston rod, transmission rod, limit block and limit switch, as shown in the figure:

2、performance

The compacting device cylinder is the compacting mechanism of the adsorption tower and is an important component for ensuring the stable use of the molecular sieve and the safe operation of the adsorption tower. Its role mainly has two major parts: First, it uses the compressed air in the adsorption tower to dynamically compress the carbon molecular sieve. That is, once the molecular sieve sinks, the cylinder will have a corresponding compensation displacement to ensure that the molecular sieve in the adsorption tower is in a compact state at all times, so as to prevent the molecular sieve from drastically moving due to the sinking of the molecular sieve and ensure the nitrogen production and purity of the nitrogen generator. stability. The second is to use the limit switch to control the position of the piston rod to control the working stroke of the molecular sieve. That is, when the molecular sieve sinks and the cylinder piston drives the piston rod to reach the warning limit switch, the system starts to alarm. If the user is possible, the molecular sieve should be shut down at this time. If continue to use, when the cylinder piston drives the piston rod to reach the stop limit switch, the system will automatically stop. In this case, molecular sieve must be added.

D.Adsorbent

Adsorption material according to customer needs to choose the international brand-name manufacturers Germany Kabo company (currently the company has temporarily suspended production, not on the domestic supply of carbon molecular sieve.), Japan Takeda, Japan Iwatani or domestic famous brand products, the normal service life of up to 10 years Long. Guaranteed nitrogen quality, purity and longevity.

E.valve

According to the customer's needs, the valve adopts BURKERT valves imported from Germany or well-known domestic brands. The reaction speed is 0.02 seconds and the service life is more than 3 million times. It has the features of simple structure, reliable sealing and fast closing speed. It is the purity of nitrogen. The basic guarantee of reliable equipment operation.

F.Intelligent controller

Siemens brand intelligent control instrument - Siemens PLC programmable logic controller and Germany BURKERT, Taiwan Yade Ke and other major brands of solenoid valves, ensure the continuous and reliable operation of the nitrogen generator.

The valve switching is controlled by the German Siemens PLC's output signal to control the Yadeke solenoid valve to implement automatic control, which is safe and reliable.

The nitrogen production equipment adopts the unqualified automatic venting system for general nitrogen, and the nitrogen analyzer can control the purity of nitrogen gas above the process requirements.

PLC controller is safe, reliable and durable. The panel can display all kinds of working status. It can implement joint control and remote control system with RS-485 interface.

LCD liquid crystal display input and output status, date, clock and other parameters. With ASI bus interface for centralized control of field devices and processes.

G.silencer

Zhejiang Tuohang Industrial Equipment Co., Ltd. controls the noise of the nitrogen-generating equipment: In the first working position of the muffler, we adopted a divergent universal spiral structure, first reducing the speed of the air flow and changing the direction of its operation, and then using an oversized area. Multi-folding pressure reducer and its sound-absorbing material (a synthetic material of glass fiber and plant fiber), further decelerate the deceleration of the airflow, decompression and absorption, control the noise generated by the nitrogen production equipment &; 80dB (A ).

H.Failed nitrogen automatic venting device

After the equipment is started, after the solenoid valve receives the control signal of the nitrogen analyzer, the nitrogen vent valve is automatically opened, the nitrogen outlet valve is closed (the time only takes 0.02 seconds), and the unqualified nitrogen is automatically vented. When the nitrogen purity reaches the target, the vent valve is automatically closed, the nitrogen outlet valve is opened, and the qualified nitrogen is output. No manual operation is required throughout the entire process. If the output nitrogen purity exceeds the standard, according to the customer's needs, in addition to the automatic emptying function, it can also signal its alarm, and upload the alarm signal and flow signal to the main control room DCS system.

As long as the equipment is started, it can be automatically operated. After the nitrogen tank is full, it can be automatically shut down. When the pressure is lower than the offline (can be set according to user requirements), it can be automatically restarted. After starting up, the purity will not be automatically vented, and nitrogen will be delivered on its own.

Technical features:

1.The equipment operates with low energy consumption, low cost, strong adaptability, rapid gas production, and easy to adjust the purity;

2.Perfect process design, optimal use effect;

3.Modular design, save floor space;

4.Easy operation, stable performance, high degree of automation, no one can run;

5.Reasonable internal components, uniform air distribution, reduce air flow high-speed impact;

6.Unique carbon molecular sieve protection measures to extend the service life of molecular sieves;

7.The use of famous brands as key components is an effective guarantee for the quality of equipment;

8.With a variety of fault diagnosis, alarm and automatic processing functions;

9.Optional touch screen display, dew point detection, energy saving control, DCS communication, etc.

Home

Home